To understand why you need pneumatic cylinders and what kind of benefits they have, as well as how pneumatic cylinders work, you need to have a firm grasp of the concept. Let’s discuss the basics of pneumatic cylinders to get answers to the most common questions that people mostly have such as “What is a pneumatic cylinder?” and “What is an actuator?”

What is a Pneumatic Cylinder?

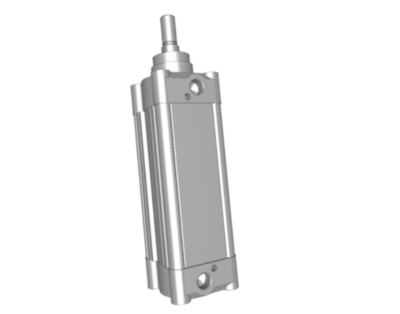

Pneumatic cylinders are also sometimes known as pneumatic actuators or air cylinders and they are mechanical devices that use compressed air energy to convert it into linear or rotary motion. This way, they provide force to automated systems and devices.

How Does A Pneumatic Cylinder Work?

The primary components of pneumatic cylinders are the following:

- Piston

- Piston rod

- Cylinder bore

So, how does a pneumatic cylinder work?

- As air flows in on one side of the cylinder, the pressure inside the cylinder increases.

- This rise makes the piston move in a particular direction.

- The piston rod transfers the created force to the object that needs to be moved.

Compared to hydraulic systems, in the case of pneumatics, cylinders use compressed air instead of fluid to work. So, pneumatic cylinders are perfect for locations that need high cleanliness. Why? It won’t contaminate the surface even in the case of leaking.

Air cylinders can be used in different applications, including industrial processes and the automation of machines. The motion and force that the cylinder creates can be used for lifting, pushing, and pulling heavy loads.

Types of Pneumatic Cylinders

When it comes to the types of pneumatic cylinders, there are two main types: single-acting and double-acting. Here's how they work.

- Single-Acting Pneumatic Cylinder

A single-acting pneumatic cylinder is one in which the rod moves in one direction only. They use one port to let pressurized air enter the cylinder and move the piston in a specific direction. In single-acting pneumatic cylinders, there is a spring attached to the piston rod. Only one side of the chamber is filled with compressed air after entering through one of the cylinder caps. Through compressing or stretching the spring, the piston and rod assembly move in one direction — linearly.

If you remove the air from the cylinder, the pneumatic piston will move back up to its original position with the help of a spring. This cylinder has two common types — pull-type and push-type.

As opposed to a pull-type cylinder, which pulls the piston inside of it, a push-type cylinder pushes the piston out of the cylinder when compressed air is applied. The single-acting cylinders are good for slower applications.

Single pneumatic cylinders have a simple design and are easier to install.

- Double-Acting Pneumatic Cylinder

Double-acting cylinders have two pistons that can extend and retract without spring. Two ports on a double-acting pneumatic cylinder regulate the rod's movement. Without the aid of a spring, the compressed air forces the rod to move in both directions. The piston is moved forward by air entering through one port, and then the piston is pulled back into the cylinder by applying compressed air into the other port.

Through these cylinders, the air enters and leaves the cylinder without any need for a spring. They are used in industrial processes such as for opening and closing doors.

Whenever you need to produce a force in both directions, you need to use double-acting cylinders.

Double-acting pneumatic cylinders have more control, are stronger, faster, and save energy. But they are more expensive compared to single pneumatic cylinders.

Benefits of Pneumatic Cylinders

- Pneumatic cylinders are compact and lightweight, making them easy to install in hard-to-reach spaces.

- They're also reliable, with long life expectancies.

- In addition to their compact size, another benefit of pneumatic cylinders is that they are a great choice for applications where the environment is harsh or electrically sensitive.

- It’s cost-effective and reliable as well.

Pneumatic cylinders and actuators offer you a wide range of benefits. They can also be used in a wide range of applications and are reliable because they don’t require frequent maintenance.

How to Select Pneumatic Cylinders

When selecting a pneumatic cylinder, consider the following factors:

- Design and stroke length

- Speed

- Air consumption

- Force output

- Materials

Pneumatic cylinders are a great choice for industrial projects, especially when combined with other pneumatic components. So, double-check our blog if you want to know pneumatic cylinders’ function and benefits.