What Is a Pneumatic Cylinder?

Pneumatic cylinders, also called air cylinders or pneumatic actuators, are mechanical devices that convert pressurized air or gas energy into a linear or rotary motion.

Pneumatic Actuator Types

There are two primary types of air cylinders:

Single-acting pneumatic cylinder

These pneumatic actuators operate on one end of the piston. They are often called spring-return actuators and open the valve using air and close it with a spring, or vice versa. When there is an absence of air pressure or power, these cylinders return to their original position. They have a limited stroke length and are suitable for slower operations. Also, they are characterized by efficiency, reliability, and lower operating costs.

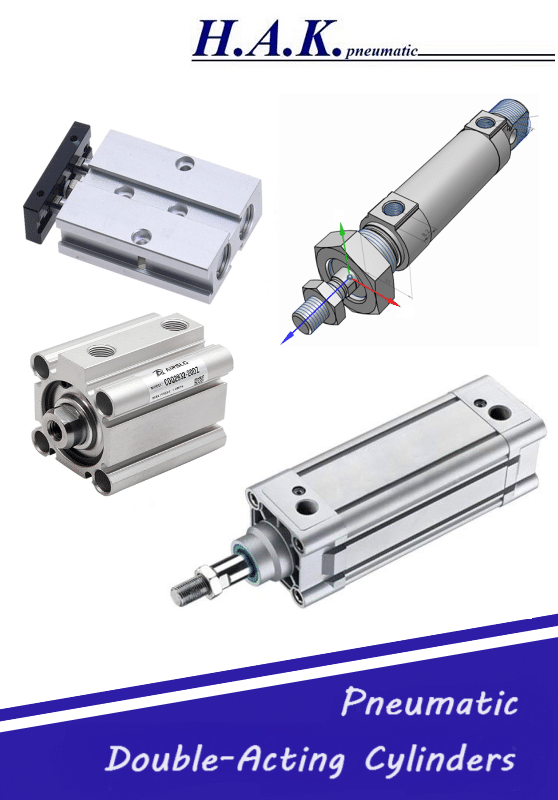

Double-acting pneumatic cylinder

The double-acting pneumatic actuator operates on both ends of the pistons. With these actuators, the opening and closing of the pneumatic valve are done through the air. The two ports of the cylinder let air enter and exit without a spring. These pneumatic air cylinders are characterized by longevity and are perfect for applications that need more than one movement.

How to Choose a Pneumatic Actuator?

These are the characteristics that you should consider while selecting a pneumatic air cylinder:

- Motion – While choosing the pneumatic actuator, you must understand whether you want the cylinder to transform the energy into a linear or rotary motion.

- Type – Cylinders fall into single-acting and double-acting categories. You should consider which type matches best with your industrial application and then choose the right pneumatic air cylinder.

- Style – When selecting a pneumatic air cylinder, you should consider whether you want it to have a rodless or piston rod actuation. Rod-style cylinders include compact, disposable, guided, repairable cylinders, etc. Rodless cylinders can move a load in a linear motion using pressurized air. They are ideal for applications that have long strokes.

- Stroke – You can also determine which cylinder to purchase if you determine which stroke length best suits your applications. There are four main categories of strokes: short, intermediate, long, and specialty. Some cylinders can correspond to all types. Short-stroke or compact cylinders can have 0.0625-inch strokes, and intermediate ones can have up to 36 inches. Long-stroke pneumatic actuators have strokes reaching 99 inches. And specialty ones have strokes sized more than 99 inches.

- Material – Pneumatic actuators can be made of various materials, such as stainless steel, aluminum, brass, etc. Some cylinders can combine all materials. It’s essential to consider the operating environment while choosing a material.

- Mounting – You should also select the right mounting style for your cylinder, considering the actuator’s function. The cylinder has accessories for mounting it to a load. Mounting identifies the attachment of a cylinder and the equipment and plays an essential role in system performance, reliability, and design.

Benefits of Pneumatic Actuators

Here are the advantages of pneumatic actuators or cylinders:

- Simple design

- Longevity

- Cost-efficiency

- Easy maintenance and installation

- High-speed operation

- Durability and versatility

If you’re searching for the perfect pneumatic actuator to suit your industrial requirements, look no further than HAK Fluid Power Equipment LTD. We’re always available and eager to assist you in finding the ideal solution for your needs