Solenoid valves are vital components in various industrial and home applications, used to control the flow of liquids or gasses. Wiring a solenoid valve correctly is important for its efficient operation. In this blog, we’ll walk you through the process of wiring a solenoid valve, ensuring that you can tackle this task with confidence.

Understanding Solenoid Valves

Before diving into the wiring process, it's essential to understand what a solenoid valve is and how it works. Solenoid valves are electromechanically operated valves, typically used to control the flow of fluids such as air, water, oil, or steam. They function by using an electric current to pass through a solenoid coil, which in turn creates a magnetic field that activates the valve, changing its state from open to closed or vice versa, thereby controlling the flow of the fluid. This mechanism makes them integral in various applications where precise control of fluid flow is necessary.

Required Tools and Materials

To successfully wire a solenoid valve, you'll need a few essential tools and materials at hand. Here's what you'll need for the task:

- Solenoid valve

- Wire strippers

- Screwdrivers

- Voltage tester

- Electrical wires

Step-by-Step Wiring Guide

Here's a step-by-step guide to help you safely and effectively wire your solenoid valve:

- Safety First: Ensure that the power supply to the circuit is turned off. Safety should always be your top priority when working with electrical components.

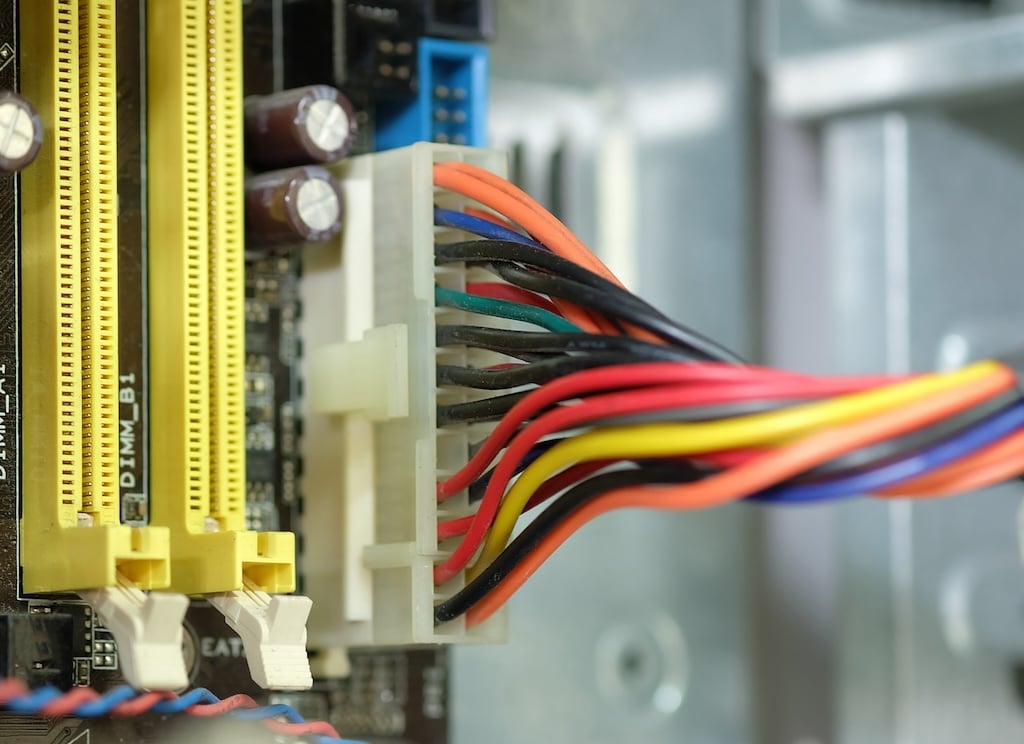

- Identify the Solenoid Terminals: Solenoid valves usually have two or more terminals. One is for the ground wire, and the others are for the power wires.

- Prepare the Wires: Using wire strippers, strip the ends of the wires you will be connecting to the solenoid valve.

- Connect the Ground Wire: Attach the ground wire to the ground terminal of the solenoid valve. Ensure the connection is secure.

- Connect the Power Wires: Connect the power wires to the appropriate terminals on the solenoid valve. If your valve has two power terminals, it doesn’t typically matter which wire connects to which terminal.

- Secure the Connections: Ensure all the wire connections are tight and secure. Loose connections can lead to malfunctions.

- Testing the Solenoid Valve: After wiring, it's crucial to test the solenoid valve. This is where understanding how solenoid valves respond to test pulses is essential. Apply a test pulse to check if the valve opens and closes correctly. Observe the response of the valve to ensure it is operating as expected.

- Final Checks: Once you are satisfied with the testing, recheck all connections and ensure everything is in place.

Troubleshooting

If the solenoid valve does not operate correctly after installation, the first step is to meticulously recheck all connections. Ensure that the power supply matches the valve's requirements and that each connection is secure and correctly aligned. Additionally, inspect the solenoid coil and the valve itself for any signs of damage or wear, as these can also impact performance. If these steps don't resolve the issue, it's advisable to refer to the valve's manual for efficient troubleshooting tips or reach out to technical support for expert guidance and assistance. Their expertise can often quickly identify and resolve issues that may not be immediately apparent.

The Role of Solenoid Valves in Modern Systems

Solenoid valves play a crucial role in modern automated systems. They are often used in fluid control systems, HVAC units, and various industrial applications. The ability of solenoid valves to be controlled remotely makes them ideal for systems where direct manual control is impractical or impossible. They provide a safe, efficient, and cost-effective solution for managing the flow of fluids, be it in controlling water for irrigation systems or regulating steam in heating systems. The versatility of these valves means they can be found in everything from simple home appliances to complex industrial machinery.

Understanding the specific requirements and limitations of your solenoid valve is key to ensuring optimal performance. Factors like pressure ratings, fluid compatibility, and environmental conditions should be considered when selecting and installing a solenoid valve. With proper installation and maintenance, these valves can offer reliable and long-lasting service, making them an indispensable part of modern automation.

Wiring a solenoid valve can be straightforward if you follow these steps carefully. Remember, safety is significant, so always ensure the power is off before starting your work. If you have any concerns or questions about wiring a solenoid valve, please don’t hesitate to contact us. We’re here to help ensure your solenoid valve setup is successful and safe.

This guide aims to make the wiring process as clear as possible, but always refer to specific product manuals for detailed instructions relevant to your particular solenoid valve model.