Description:

The H.A.K. Pneumatic Stainless-Steel Piston-Operated Angle Seat Valve is a high-performance valve designed for precise and reliable flow control in demanding industrial applications. Its stainless-steel construction ensures superior durability and corrosion resistance, making it suitable for harsh environments. The angle seat design provides optimal flow and reduces pressure drop. At the same time, the Normally Closed (NC) configuration keeps the valve closed when de-energized, ensuring that no flow occurs until actuated. This valve is ideal for high-temperature and high-flow applications in various industries.

Key Features:

- Type: Piston-operated angle seat valve.

- Material: Robust stainless-steel body for maximum corrosion resistance and longevity.

- Operation: Normally Closed (NC) – remains closed when not actuated.

- Port Size: 1/2" NPT for efficient media flow.

- Media Compatibility: Suitable for air, steam, gases, and liquids.

- High-Temperature Capability: Designed for steam and hot media applications.

- Flow Efficiency: Angle seat design reduces pressure drop and enhances flow rates.

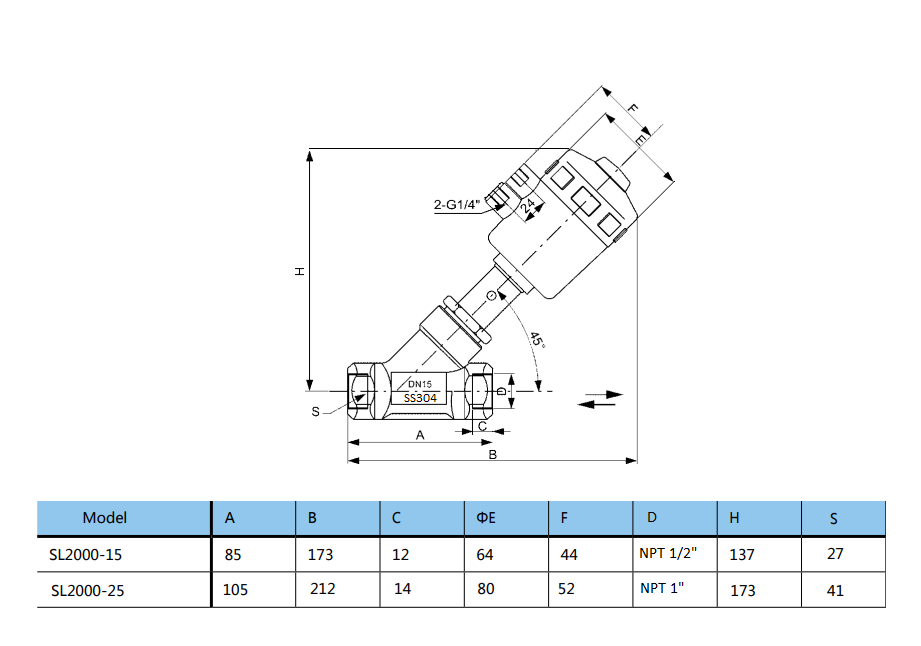

Dimensions:

Specification:

| Model | SL2000-15-S-NC |

|---|---|

| Working Medium | Air, Steam, Gases, liquids |

| Operation | Piston-operated |

| Type | Normal Close |

| Port Size | 1/2" NPT |

| Max. Working pressure | 0-1.6kg/cm2 (0-232psi) |

| Min. Pilot Pressure | 3.9kg/cm2 (55.47psi) |

| Working Temperature | -10~120 ℃ |

| Medium viscosity | Max600mm²/s |

| CV Value | 4.8552 |

| Material of Body | Stainless Steel 304 |

How It Works

The piston-operated angle seat valve utilizes compressed air to control the piston that opens and closes the valve. In its normally closed position, the valve prevents media from flowing. When pneumatic pressure is applied, the piston moves, opening the valve and allowing flow. The angle seat design promotes an uninterrupted flow path, allowing for efficient media transfer even in high-temperature and high-pressure environments.

Operation:

- Normally Closed: In its default state, the valve is closed, preventing flow.

- Pneumatically Actuated: When compressed air is applied, the piston activates, moving the seat to open the valve and permit flow.

This design is ideal for applications requiring the valve to remain closed until actuation, providing reliable sealing when not used.

Advantages:

- Fast Actuation: The piston mechanism enables quick and accurate valve operation.

- Durable Stainless Steel: Offers excellent resistance to wear, corrosion, and high temperatures, ensuring longevity in harsh environments.

- Optimized Flow: Angle seat design minimizes flow restrictions and pressure loss, enhancing overall system efficiency.

- Versatility: It is suitable for various media, including liquids, gases, and steam, making it adaptable across industries.

- High-Temperature Resistance: Ideal for steam applications and other high-heat processes.

Industry Applications

- Food and Beverage Processing

- Pharmaceutical Production

- Chemical Processing

- Textile Industry

- Water Treatment Plants

- HVAC Systems

Additional information

| Weight | 0.898 kg |

|---|---|

| Dimensions | 11.5 × 4.5 × 3 in |