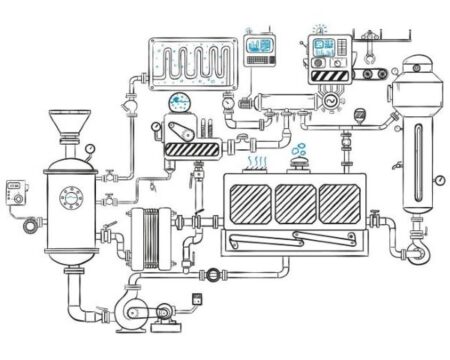

Pneumatic systems, the quiet champions of modern industry, work tirelessly behind the scenes to drive many vital processes. Whether it's the bustling floors of manufacturing plants or the safety-critical brakes in vehicles, these systems owe their efficiency to the magical force of compressed air.

But here's the catch: like your car needs an oil change or your smartphone needs regular updates, pneumatic systems also demand some TLC. In this article, we're about to embark on an exciting journey into the world of pneumatic systems. We'll uncover the secrets of their inner workings, and equip you with indispensable knowledge about maintaining those. So, let's dive in and discover the fascinating world of pneumatic systems together!

Routine Maintenance for Pneumatic Systems

When we evaluate pneumatic systems in comparison to other mechanical counterparts, they tend to encounter fewer issues. However, it's essential to emphasize that this doesn't imply they can operate indefinitely without any maintenance. While the problems that do arise are generally less complex and easier to rectify than those in other systems, this holds true only when proper maintenance and care are consistently provided.

In essence, pneumatic systems experience fewer troubles when they receive proper maintenance.

Inspect for Leaks

Leakage represents a critical and widespread issue in pneumatic systems, and when left unattended over an extended period, it can trigger a cascade of problems. These issues include placing additional stress on the system, squandering precious compressed air, inflating maintenance and operational costs without delivering commensurate benefits, and potentially undermining the quality of production.

Thankfully, despite its frequent occurrence, air leakage is a challenge that lends itself to relatively straightforward detection and resolution. This ease of identification is owed to the fundamental behaviour of air—it tends to escape with noticeable sounds, readily catching the attention of those monitoring the system. Even in instances where the leakage is exceptionally minor and does not audibly manifest as escaping air, a practical solution is readily available: applying a mixture of soap and water to the suspected area.

When no leakage is present, the soap and water concoction will remain undisturbed. However, the presence of an air leak becomes evident through the formation of air bubbles. For a more precise approach to detecting and sealing leaks, ultrasonic leak detectors can also be employed.

Upon pinpointing the source of the leakage, you are presented with several avenues for addressing the issue. You can simply tighten the glands or joints securely to mitigate minor leaks. In cases of substantial or irreparable leakage, it may be prudent to contemplate replacing the compromised component with a new one. Additionally, there exists a diverse array of bonding products specifically tailored for commercial applications available in the market. These products can be effectively utilized to rectify the issue, offering an efficient solution to seal the leakage and restore the pneumatic system to its optimal functionality.

Change Filter

Air filters play a pivotal role in maintaining the quality of air within a pneumatic system and preventing contaminants from infiltrating critical components. It's imperative to adhere to recommended filter replacement intervals to uphold efficient filtration. By doing so, you ensure the compressed air's continued purity and safeguard the system's sensitive elements from damage or performance degradation.

Lubricate Components

Proper lubrication is the lifeblood of pneumatic components, ensuring their longevity and smooth operation. Lubricators are indispensable in maintaining the frictionless movement of pistons and cylinders. To maximize their effectiveness, it's essential to use a lubricant that is compatible with the specific pneumatic system in use. Regular lubrication not only enhances component life but also contributes to overall system reliability.

Inspect Hoses and Tubing

Regular inspection of hoses and tubing is a fundamental aspect of pneumatic system maintenance. Wear, cracks, or damage to these components can compromise the integrity of the entire system. Timely replacement of any compromised hoses or tubing is essential to prevent system failure and avoid potential safety hazards. Vigilant monitoring of these components is key to ensuring uninterrupted pneumatic system operation.

Check Pressure Gauges

Accurate pressure gauges are indispensable for monitoring and maintaining the optimal operating conditions of a pneumatic system. Incorrect pressure readings can lead to inefficiencies, system malfunctions, and even safety hazards. Regularly verify that pressure gauges are functioning correctly and providing accurate readings. By doing so, you can maintain the system's efficiency and reliability, ensuring it operates within safe and optimal pressure ranges.