Pneumatic valves are an important component in pneumatic systems utilized to regulate the flow and direction of compressed air. They are used vastly in automation, machine tools, and manufacturing processes where fine airflow control is essential.

Prior to understanding the different types of pneumatic valves, let's discuss the basics of pneumatics and the operation of a pneumatic system.

What Are Pneumatics?

The term pneumatics comes from the Greek word pneuma, meaning "air" or "breath," an indication of the use of compressed air as the power source. Pneumatic systems then use this compressed air to create motion, drive mechanical equipment, and drive automation processes.

A typical pneumatic system consists of:

-

An air compressor to provide compressed air

-

An air receiver tank to store it

-

Control devices like valves and actuators to guide and control airflow

How Does a Pneumatic System Work?

Pneumatic systems function in much the same manner as hydraulic systems, but instead of using liquid, they use compressed air. The following is how it is accomplished:

-

The air is forced into a storage tank by the compressor.

-

Valves control the release of air.

-

The air travels through tubing to pneumatic tools or actuators.

At the heart of this system are pneumatic valves, which thoughtfully determine when and where air is released to perform mechanical work.

What is a Pneumatic Valve?

A pneumatic valve, or a directional control valve, controls the flow, pressure, and direction of air in a pneumatic system. Pneumatic valves act as an intermediary between the compressed air source and the actuator or device being powered.

Depending on the system requirements, pneumatic valves may be controlled:

-

Manually

-

Electrically

-

Mechanically

-

Pneumatically (air-powered)

Choosing the right valve is a function of desired control mode and application complexity.

Types of Pneumatic Valves

Pneumatic valves may be categorized by:

-

Actuation method (manual, electric, etc.)

-

Number of ports (entry/exit points)

-

Function (directional control, pressure regulation)

-

Default position (normally open or closed)

-

Flow path configuration (how air passes through the valve)

Let's discuss the most common ones:

1. Two-Way Pneumatic Control Valves

These are two ports and two positions: open and closed. Air from one port to the other when open; airflow is blocked when closed.

Applications:

Ideal for simple on/off flow control in one direction.

2. Three-Way Directional Control Valves

Three-way valves are three ports and two positions:

-

One for intake of air

-

One for output of air

They reverse airflow and venting to a single-acting device or actuator.

Applications:

Used where air must be alternately supplied and exhausted.

3. Four-Way Pneumatic Control Valves

The four-way valves consist of four ports:

-

Two for connecting to the actuator

-

One for supply of compressed air

They are typically used in double-acting cylinders and can reverse direction of travel.

Typical configurations:

2/2-way

3/2-way

4/2-way

5/2-way

5/3-way

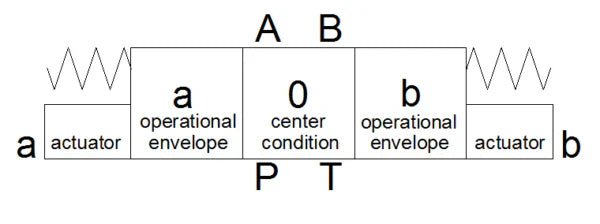

4. Spring-Offset Pneumatic Valves

Here, a spring mechanism brings the valve back to its original position when the actuating force is removed.

A spring-return directional valve returns to its original position automatically after it is used, promoting fail-safe operation.

Applications:

Where a valve needs to return to a predetermined position when de-energized.

Conclusion

Pneumatic valves play a very important role in the functioning and safety of pneumatic systems. From a straightforward two-way valve for on/off flow control to a more sophisticated four-way valve for reversing motion, all types have distinct functions.

When choosing a pneumatic valve, take into consideration:

-

Your system's pressure and flow requirements

-

The control method

-

The desired flow direction and port configuration

Having difficulty choosing the right pneumatic valve for your application? Contact us or read additional articles on our industrial automation blog.