The automation of mechanical operations in a variety of sectors relies heavily on pneumatic cylinders. Proper and frequent maintenance, especially lubrication, is crucial for preserving the longevity and efficiency of these cylinders. The necessity of maintaining these cylinders' proper lubrication is highlighted in this thorough book, which explores the essential elements of pneumatic cylinder maintenance.

This blog guarantees the smooth and dependable operation of your pneumatic systems, from choosing the right oil to comprehending the subtleties of the lubrication procedure. To make sure the maintenance procedure is both efficient and safe, we'll also go over the crucial safety precautions that must be taken.

Why Lubrication is Critical

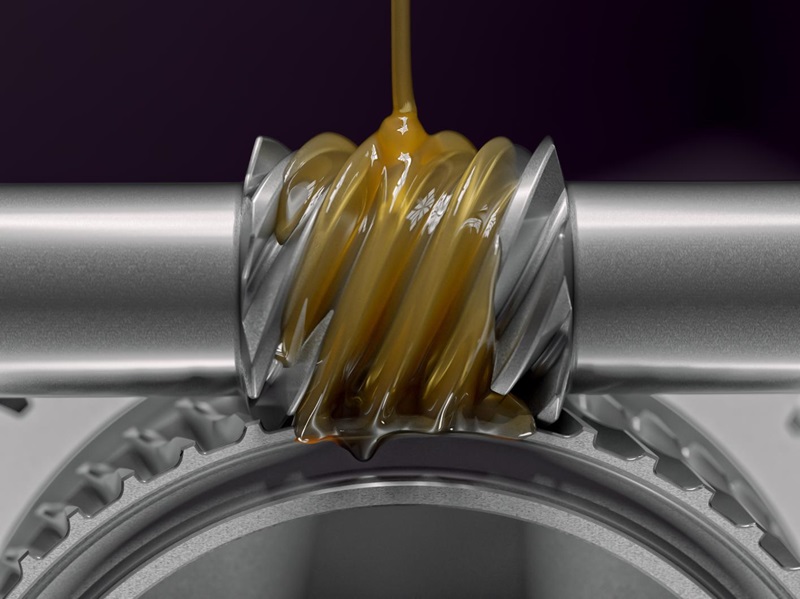

Lubrication is an essential investment in the longevity and performance of pneumatic cylinders, not just a maintenance chore. When moving parts are properly lubricated, wear is reduced and the equipment's lifespan is increased. Additionally, it aids in maintaining the integrity of the seal, stopping air leaks and guaranteeing reliable operation. Cylinders may experience greater wear and tear and costly downtime and repairs if they are not properly lubricated.

Frequency of Lubrication

Determining how often to lubricate your cylinders is crucial. While the manufacturer's guidelines provide a baseline, factors like usage intensity, operating conditions, and the type of lubrication system in use can influence the frequency. Regular monitoring for signs of wear or changes in performance can also help establish a more tailored lubrication schedule.

The Lubrication Process

Understanding how to lubricate a cylinder properly is essential for effective maintenance. The process typically involves applying a specified amount of oil to the air inlet, ensuring it's distributed evenly throughout the system as the cylinder operates. For systems with an integrated cylinder lubrication system, maintenance may involve checking the oil level and replenishing it as needed.

Safety Measures During Lubrication

Safety should always be a priority when performing maintenance on pneumatic cylinders. Ensure the system is depressurized and the power source is disconnected to prevent accidental activation. Wear appropriate protective gear, and be mindful of the potential for spills, which can create slip hazards. Properly dispose of used oil and rags to avoid environmental harm and fire risks.

Dos of Pneumatic Cylinder Lubrication

- Choose the Right Lubrication Oil: Selecting the appropriate lubrication oil for pneumatic cylinders is crucial. It should be compatible with the cylinder's materials and the working environment. Oils designed specifically for pneumatic systems offer the best protection and performance.

- Use a Cylinder Lubrication System: Implementing a cylinder lubrication system can automate the lubrication process, ensuring consistent oil application throughout the system. This not only optimizes the cylinder's operation but also extends its service life.

- Apply Lubricant Properly: Knowing how to lubricate a cylinder correctly is essential. Apply lubricant to the air inlet before attaching it to the cylinder. This method ensures an even distribution of oil inside the cylinder, protecting against wear and tear.

- Regular Maintenance Checks: Incorporate lubrication checks into your regular maintenance schedule. Monitoring the lubrication levels and the condition of the oil can prevent potential issues related to under-lubrication or contamination.

- Consult Manufacturer Guidelines: Always refer to the manufacturer’s manual for specific lubrication recommendations. This includes the type of oil to use, the frequency of lubrication, and any special instructions for your particular model.

Don'ts of Pneumatic Cylinder Lubrication

- Avoid Over-Lubrication: While oiling a cylinder is crucial, too much lubricant can lead to buildup and contamination, impairing the system's performance. Adhere to the recommended lubrication amount and frequency.

- Don’t Use Incompatible Oils: Not all lubrication oils are suited for pneumatic systems. Using the wrong type can damage seals and other components. Ensure the oil is designed for pneumatic use and is compatible with your cylinder's materials.

- Don't Neglect Environmental Conditions: Environmental factors such as temperature, humidity, and the presence of corrosive substances can affect lubrication needs. Adjust your lubrication practices according to these conditions to maintain optimal performance.

- Avoid Mixing Different Oils: Mixing lubricants can cause chemical reactions that degrade the oil's effectiveness and can harm the cylinder components. Stick to one type of oil unless a complete system flush is performed.

- Don't Ignore Signs of Lubrication Issues: Unusual noises, decreased performance, or increased friction are signs that your pneumatic cylinder may require attention. Promptly addressing these signs can prevent more significant problems down the line.

An essential part of maintaining a pneumatic cylinder is proper lubrication. You can guarantee the longevity and effectiveness of your pneumatic systems by adhering to these dos and don'ts, which include selecting the proper lubrication oil for pneumatic cylinders, putting in place a methodical cylinder lubrication system, and understanding how to lubricate a cylinder efficiently.

Maintaining your equipment in accordance with manufacturer instructions and doing routine maintenance also helps it operate at its best. To ensure a profitable and well-functioning pneumatic system, remember these procedures.