In the industrial landscape, pneumatic systems are the driving force behind countless manufacturing processes, making them a vital component in various industries. However, to ensure their seamless operation and cost-effective performance, maintaining optimal airflow efficiency is essential. In this detailed guide, we'll explore ten comprehensive tips to enhance airflow efficiency in pneumatic systems, unravelling the intricacies of each recommendation.

Tip 1: Maintain Clean Air

The quality of compressed air directly impacts a pneumatic system's performance. Airborne contaminants, including dust, moisture, and oil, can infiltrate the system, leading to clogged filters and malfunctioning valves. To mitigate this issue, it's crucial to install high-quality air filters and dryers. Regularly inspect and clean or replace filters as needed to ensure a continuous supply of clean, dry air to your pneumatic system.

Tip 2: Optimize Pressure Settings

Efficient pressure management plays a pivotal role in minimizing energy consumption and maximizing airflow efficiency. Begin by carefully calibrating your system's pressure settings to meet its specific operational requirements. Operating at higher pressures than necessary can result in energy waste, as well as increased wear and tear on system components. A well-calibrated pressure setting ensures that your pneumatic system operates at peak performance while conserving energy.

Tip 3: Monitor for Leaks

Air leaks are silent culprits that can significantly impact airflow efficiency and increase operational costs. Regularly inspect your pneumatic system for leaks using effective methods such as ultrasonic leak detection devices or soap bubble tests. Detecting and repairing leaks promptly not only prevents energy wastage but also extends the lifespan of system components, reducing maintenance costs in the long run.

Tip 4: Proper Lubrication

For pneumatic systems that require lubrication, choosing the right lubricants and applying them correctly is essential. Over-lubrication can lead to the accumulation of contaminants, increasing the risk of component failure. Conversely, under-lubrication can result in premature wear and reduced efficiency. Refer to your system's documentation to determine the precise type and quantity of lubrication required for each component, ensuring optimal performance and longevity.

Tip 5: Select Efficient Components

The components within your pneumatic system significantly influence airflow efficiency. When designing or upgrading your system, prioritize high-quality valves, actuators, fittings, and other components. Here at Hakpneumatic.com, we offer efficient and reliable pneumatic components known for their performance and longevity. Choosing the right components ensures that your system operates with maximum efficiency and minimal energy consumption.

Tip 6: Implement a Maintenance Schedule

Regular maintenance is the backbone of a well-functioning pneumatic system. Develop a comprehensive maintenance schedule that encompasses essential tasks such as filter replacement, lubrication checks, valve inspections, and leak detection. Adhering to this schedule not only prolongs the life of your system but also minimizes downtime, reducing operational costs and enhancing overall efficiency.

Tip 7: Train Your Team

A knowledgeable and skilled maintenance and operations team is vital for the effective management of pneumatic systems. Invest in training programs to ensure that your team comprehensively understands the system's intricacies, can identify potential issues, and performs routine maintenance tasks effectively. Well-trained personnel are essential for maintaining optimal airflow efficiency and minimizing system downtime.

Tip 8: Employ Energy-Efficient Practices

Incorporating energy-efficient practices into your facility's operations can further enhance airflow efficiency and reduce operational costs. Consider scheduling pneumatic system operations during off-peak hours to take advantage of lower energy rates. Utilize variable-speed drives that adjust airflow based on demand, optimizing energy usage. Implement smart control systems that automatically manage pressure and airflow, ensuring that your system operates at its most efficient levels.

Tip 9: Regularly Monitor Performance

Modern pneumatic systems offer advanced monitoring and control capabilities, providing real-time data and alerts. Leveraging these features allows you to continuously monitor your system's performance. By tracking airflow rates, pressure levels, and other critical parameters, you can quickly detect inefficiencies or abnormalities. Timely intervention based on the data provided by your monitoring system ensures that your pneumatic system consistently operates at peak efficiency.

Tip 10: Seek Professional Assistance

When faced with complex issues or uncertainties regarding your pneumatic system's efficiency, it's advisable to seek the expertise of pneumatic system professionals. They can conduct comprehensive assessments, diagnose problems accurately, and recommend tailored solutions. Professional guidance ensures that you address airflow inefficiencies effectively and maintain your system's optimal performance.

Tip 11: Consider Advanced Control Systems

Advanced control systems, such as Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems, can further enhance the efficiency of your pneumatic system. These systems offer precise control over various parameters, allowing you to fine-tune your system's operation for maximum efficiency. By integrating advanced control systems into your pneumatic setup, you gain the capability to automate processes, optimize energy consumption, and respond rapidly to changing operational requirements.

Troubleshooting Pneumatic Systems

Despite implementing the best practices mentioned above, pneumatic systems may encounter issues that require troubleshooting. To ensure uninterrupted operation, it's essential to have a set of troubleshooting techniques in your arsenal. You can check tips to troubleshoot pneumatic systems for in-depth guidance on identifying and resolving common pneumatic system problems.

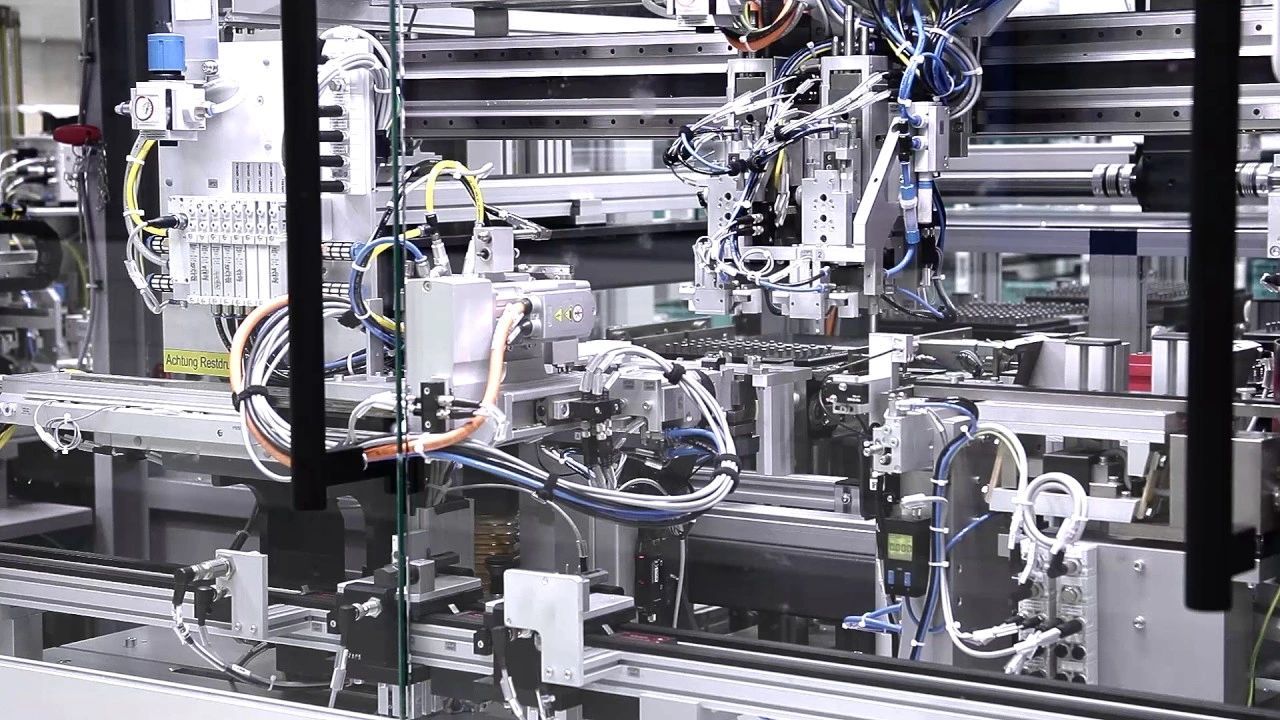

Components of a Pneumatic System

Understanding the various components of a pneumatic system is fundamental to optimizing its airflow efficiency. Components such as compressors, air reservoirs, valves, actuators, and filters all play unique roles in the system's operation. Familiarizing yourself with the functions and maintenance requirements of these components contributes to effective airflow management.

Enhancing airflow efficiency in pneumatic systems is a multifaceted endeavour that requires attention to detail and proactive maintenance practices. By meticulously following these ten comprehensive tips, you can optimize your pneumatic system's performance, reduce energy consumption, and extend its operational lifespan. Clean air, calibrated pressure settings, leak detection, proper lubrication, efficient components, regular maintenance, trained personnel, energy-efficient practices, performance monitoring, and professional guidance together form the foundation of an airflow-efficient pneumatic system.

Embracing these practices not only ensures the reliability and cost-effectiveness of your system but also contributes to overall operational excellence in your facility. So, take the initiative today and breathe new life into your pneumatic systems.